Auto Lube

Malloy can help with your specification and selection of the proper auto lubrication system for your turbine. There are 6 primary points that should be evaluated for auto lubricators

Generator Bearings | Main Shaft Bearings | Pitch Bearings | Pitch Gears | Yaw Bearings | Yaw Gears

The extended lubrication intervals in Wind applications lead to exagerated over and under lubricated operating conditions. An automatic lubricator system delivers small doses frequently to ensure the bearing lubrication level remains at the optimal level at all times. The automatic lubricator can also operating while the bearing is rotating. This will help the grease get drawn in to the roller path, exactly where it needs to be.

Mini series

The mini series unit is a compact unit perfectly sized for generator bearings.

Easy to program controller

Controller screen on unit

Made in the USA!

G3 Pro Series

The G3 Pro series is the workhorse for a Wind turbine application. With large reservoir sizes and additional options available this is suited for Main Bearing, Yaw bearing, Yaw Gear, Pitch Bearing and Pitch Gear lubrication applications.

Easy to program controller

Controller screen on unit

Made in the USA!

Up to 15L reservoir size

Optional follower plate

Low level alarm

G3 Max Series

With the same features as the G3 Pro but additional capabilities for customized alarm feedback and system monitoring for critical wind turbine applications.

Same features as G3 Pro and more

Cycle count alarm

Custom alarm feedback

Download data logs

And more…

Related content

-

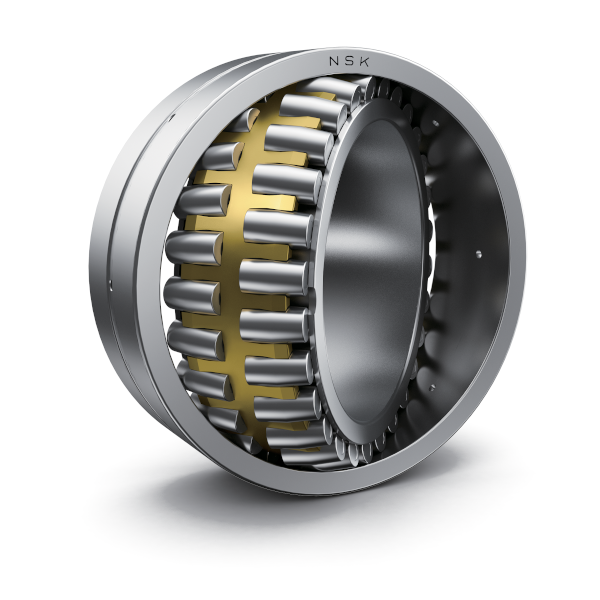

Main Shaft Bearings

Upgraded bearing materials can dramatically improve bearing life even with poor lubrication.

-

Super Tough Bearings

From the steel alloy to the heat treatment, Super Tough bearings are upgraded for the most demanding applications.

-

Blade Bearing Ring Cracks part 1

Outer ring cracks on blade bearings of a WTG can lead to loss of a blade. It’s critical to identify early and shutdown the turbine to plan for replacement.

-

Blade Bearing Cage Failures

Root cause of cage failures in Blade Bearings.